Thermocouple, Sulfur Processing Service, Compact, ATEX, IECEx

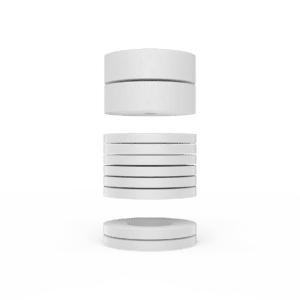

The Delta Controls Model HTS Thermocouple is designed for the primary purpose of reliably protecting a vessel and its refractory lining from excessive temperatures. The HTS is designed to accommodate a wide range of process connections starting at 2 inch Class 150 raised face flange. The HTS provides long term accuracy and reliability in sulfur processing service.

The design of the HTS is the result of attention to detail, more than 50 years of experience, and numerous field installations. The thermocouple junction is isolated from corrosive and invasive gases by using a constant low-flow flush gas circulating across the junction. The flush gas is kept at a pressure higher than the internal reactor pressure to mitigate the migration of process gases through the primary thermowell, body, or seals. Process gases that enter are carried away by the flush gas. The metered flush gas flow has an insignificant effect on the accuracy of the temperature measurement.

The HTS cylindrical body design offers multiple size configurations that allow for minimal impact of weather shroud designs, including the Temperature Extension option.

The all 316 Stainless Steel HTS is built to meet each customer’s specific installation requirements, such as thermocouple type and insertion length. Installation tools are available, and recommended to accurately produce the refractory borehole in the correct size and alignment needed by the refractory thermowell and HTS Thermocouple assembly.

Features

- Compact thermocouple utilizing verified technologyfor sulfur processing service

- Worldwide standard for protecting Claus thermal reactors

- Maintenance free

- Remains accurate under extreme conditions

- Protects and extends the useful life of refractory and improves reactor up-time

- The only proven thermocouple technology to function reliably long term in sulfur service

Specifications

- Thermocouple Types: B, R, S (others available)

- Body Material: Stainless steel

- Trim, Bolting, and Seats: Stainless steel

- Housing Material:Aluminum or 316 Stainless Steel

- Primary Thermowell Material: Blended alumina ceramic

- Threaded Process Connection: ANSI 2.0, 3.0 in MPT

- Flanged Process Connection: ANSI 2.0 in, 3.0 in, 4 in, 6 in (other sizes, types ratings available)

- Flush Gas: Nitrogen (11 L/h)

- Working Pressure: 150 psig (10.3 bar) at 500 °F (260 °C)

- Working Temperature: 0 °F to 3100 °F (-18 °C to 1704 °C)

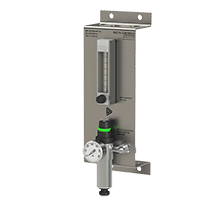

- Required Accessories: Model HFS Flush Gas Station, Model HNP Nozzle Packing Kit, Model HRW Refractory Thermowell* *For nozzles 4 inches or larger

Certifications & Approvals

- 70131733 Ex db IIB + H2 T3 Gb Class I Zone 1, AEx db IIB + H2 T3 Gb

- Sira 18ATEX1044x II 2G, Ex db IIB + H2 T3 Gb Ta = -40 °F to +176 °F (-40 °C to +80 °C)

- IECEx SIR 18.0012x Ex db IIB + H2 T3 Gb

- EAC TR CU 012/2011

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Documentation & testing packages (if required)

- Installation Details

Nozzle inside diameter

Shell thickness

Nozzle inside height

Refractory thickness

Nozzle angle from vertical

Related Downloads

- CSA Certificate of Compliance

- EU Declaration of Conformity

- IECEx Certificate of Conformity

- Application Data Form – Large Nozzles

- Application Data Form – Small Nozzles

- HTS IOM