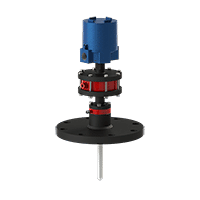

Refractory Mandrel, For Use with all Delta Thermocouples

The Delta Controls Model HRM Refractory Mandrel is designed for installation on the thermocouple nozzle prior to installing the refractory material. It creates a centered, accurate hole through the refractory lining, and the attached stop disc keeps refractory mortar from accumulating in the nozzle interior. The stop disc is required so the HRW Refractory Thermowell is positioned correctly in relation to the mounting flange.

The HRM is used when core drilling is undesirable, such as when water (for drilling) may not be used. Use of the HRM will require cutting and fitting the refractory firebrick around the tapered mandrel pipe.

Features

- Allows for optimal thermocouple installation without drilling

- Produces concentric refractory hole drilling

- Available for multiple nozzle sizes

Specifications

- Material: Carbon steel

- Flange Sizes: 4.0 in to 6.0 in

- Class: 4 in Class 150 to 6 in Class 300

- Nozzle Inside Diameter: 3.4 in to 6.0 in

- Insertion: As required

Required Ordering Information

- Detailed model number

- Documentation & testing packages (if required, refer to Additional Resources in the product catalog)