Float Switch, Side Inserted, Single Point

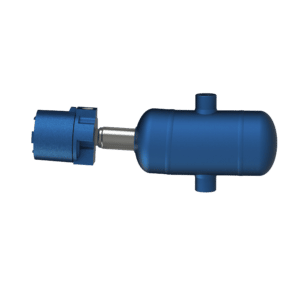

The Delta Controls Model 735 Float Switch’s small design easily handles high pressures and temperatures, and is immune to most heavy vibrations.

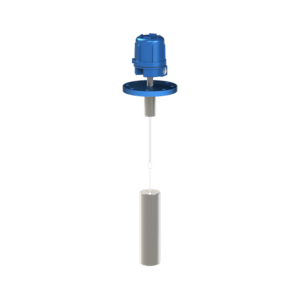

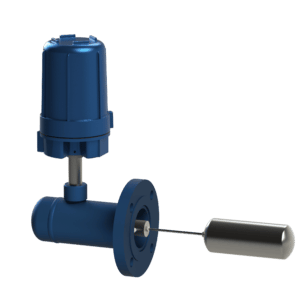

The 735 provides switch action as the liquid moves past a fixed point on the side of the vessel or tank. The float is inserted into the vessel through a flanged or threaded connection. The vessel connection must be located at the elevation where switch action is to occur.

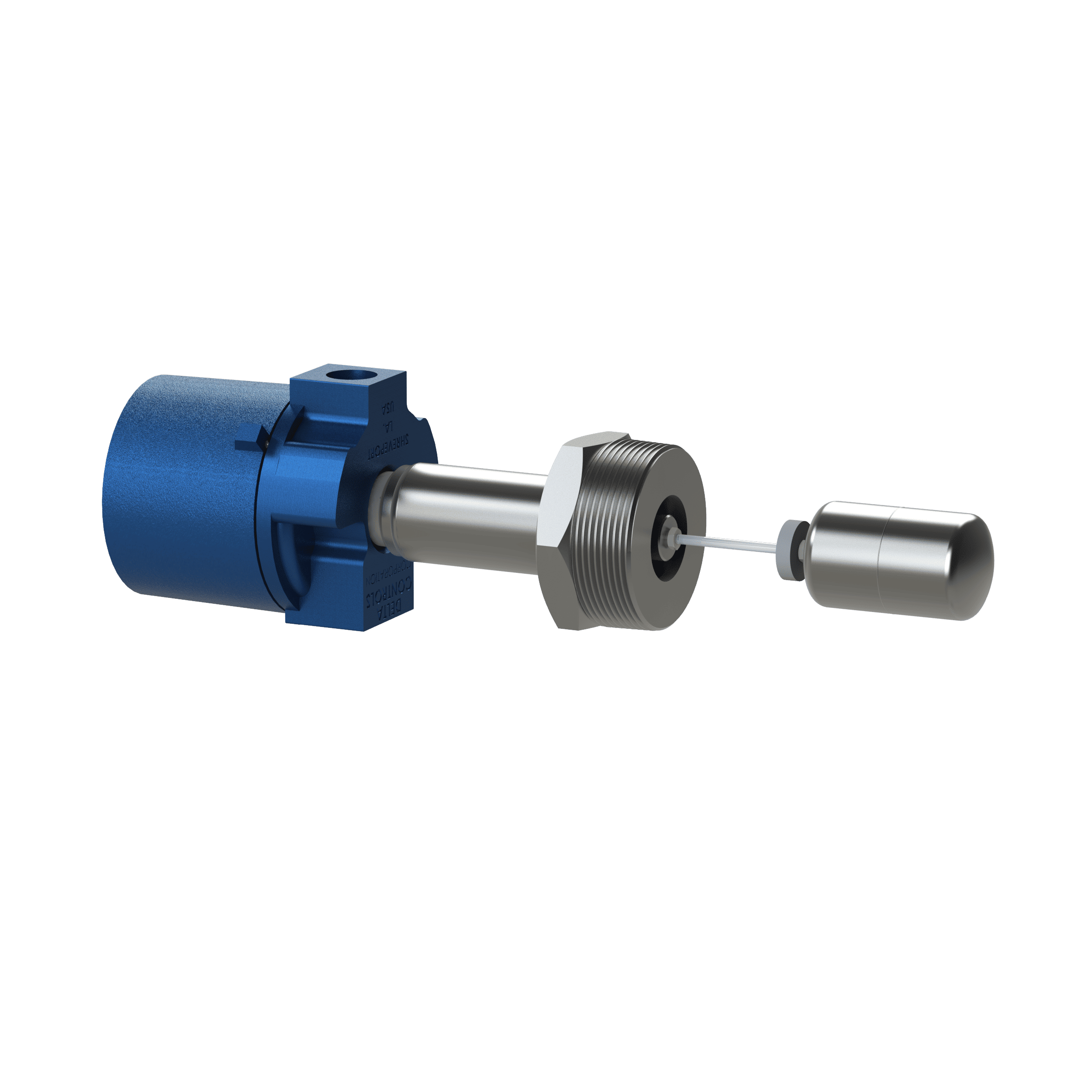

This type level switch uses a counterbalance principle which allows the use of smaller, heavy wall floats. The use of these heavy-duty floats significantly improves the safety and reliability of the switch. The purpose of the counterweight is to offset the extra weight of the heavy duty float. This results in the element only having to provide enough flotation to operate the switch magnet. In addition, the element is smaller, which allows the use of smaller process connections.

A counterbalanced float is held in a horizontal position by a pivot mechanism. As the liquid level rises, the float moved upwards. This movement results in a rotary motion of the drive magnet, which carries it into the field of the switch station magnet. The switch station magnet is driven against the outside of the sealing tube and the output switch is actuated.

Similarly, as the liquid level falls, the sensing element moves downward. The drive magnet is rotated back through the field of the switch station magnet. The switch station magnet is operated, returns to its original position, and the output is deactuated. This dual opposed magnet design provides snap action, immunity from vibration, and greatly improves reliability.

Features

- Single alarm point

- Horizontal side inserted float type level switch

- Highly reliable design

- Dual opposed magnets

Specifications

- Wetted Materials: 304 Stainless Steel, 316 Stainless Steel, Hastelloy® C-276, carbon steel

- Switch Action: Single point alarm

- Insertion (From Process Connection): 12 in to 24 in

- Specific Gravity: 0.50 to 2.40

- Temperature Range: -85 °F to +1000 °F (-65 °C to +538 °C)

- Pressure Range: -15 psig to +2250 psig (-1 bar to +155.1 bar)

- Threaded Process Connection: 1.0 in to 3.0 in

- Flanged Process Connection:2.0 in to 8.0 in

- Flange Rating: ≤ 900 lb ANSI flanges or Greloc® hub DIN or JIS equivalents

Certifications & Approvals

- Third Party Listed by CSA NRTL/C (USA and Canada) Class I, Division 1, Groups B, C and D; Class II, Division 1, Groups E, F and G; Class III, Division 1 Class I, Zone 1, Ex d IIB+H2 Class I, Zone 1, AEx d IIB+H2

Required Ordering Information

- Detailed model number

- Tag or nameplate detail (if required)

- Documentation/testing tiers (if required, refer to Additional Resources in the product catalog)

- Process fluid or material name*

- Process fluid or material specific gravity

- Maximum process temperature

- Maximum process pressure

- Upper and lower materials required for interface service