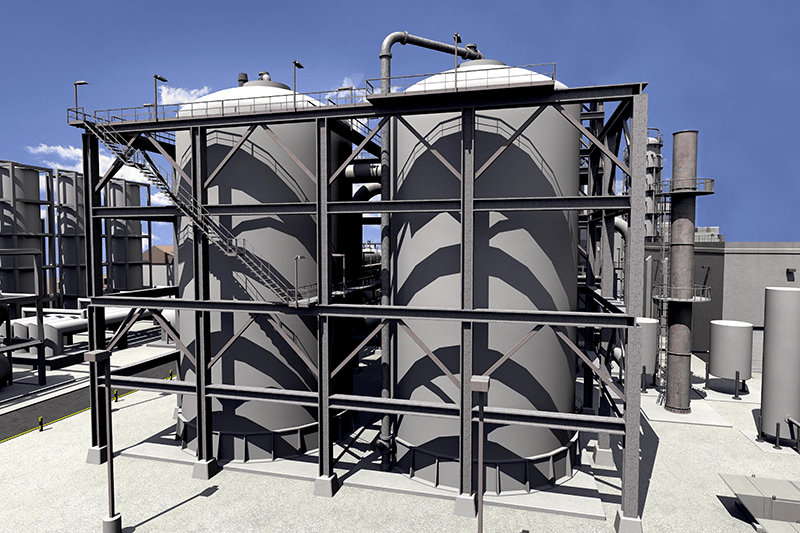

Application Overview

An exhaust gas scrubber, or packed bed scrubber, removes gaseous contaminants from airstreams and may transfer the converted steam for further use in various applications. The exhaust gas is bottom-fed into the scrubbing unit and then travels upwards through the packing material while a scrubbing liquid irrigates downwards from the top of the unit.

The liquid scrubber removes contaminants by absorbing and/or reacting with the contaminants. The clean gas is vented, typically to the atmosphere. Level measurement and point level detection of the liquid is required to ensure quality parameters are met and for efficient operation.

The Delta Controls Benefit

- Insensitivity to process coatings offers maintenance-free operation

- Simple installation and setting adjustments available on onboard menus or HART® controller

- Robust probe design provides parallel ground reference for accurate and reliable measurements

Process Data

Measurement Type

Level measurement and point level detectionInstallation Vessel

TowerTypical Range

65 feet (20 meters)Material

Contaminated gas and scrubbing liquidTypical Process Temperature

+68 °F to +248 °F (+20 °C to +120 °C)Typical Process Pressure

+14 psi to +2900 psi (+1 bar to +200 bar