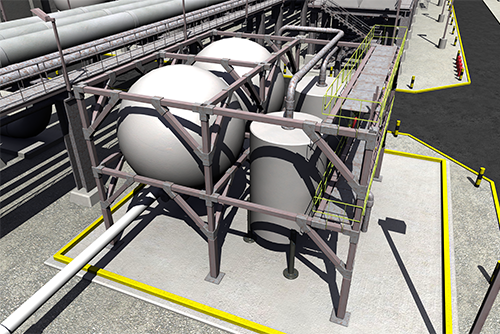

Application Overview

Refineries safely release process and / or byproduct liquids including hydrocarbons using blowdown drums. The key function of a blowdown vessel is to receive blowdown from the boiler and discharge it safely after reducing the pressure and temperature. Constant temperature, pressure and level measurement is needed due to fluctuating mixture of medias, density and viscosity to ensure that the process continues in a favorable fashion.

The Delta Controls Benefit

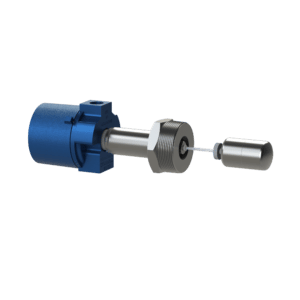

- Simple installation and setting adjustments available on onboard menus or HART® controller

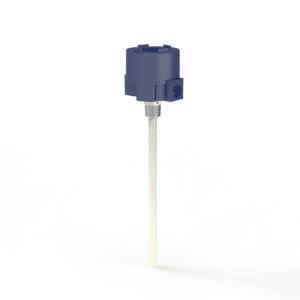

- Innovative ceramic probe design provides long-term reliability in high temperature applications

- Simple mechanical design offers maintenance-free operation

Process Data

Measurement Type

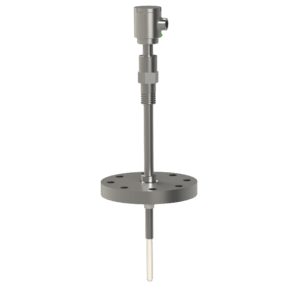

Level measurement and point level detectionInstallation Vessel

TankTypical Range

33 feet (10 meters)Material

HydrocarbonsTypical Process Temperature

+149°F to +653 °F (+65°C to +345°C)Typical Process Pressure

+15 psi to +290 psi (+1 bar to +20 bar)